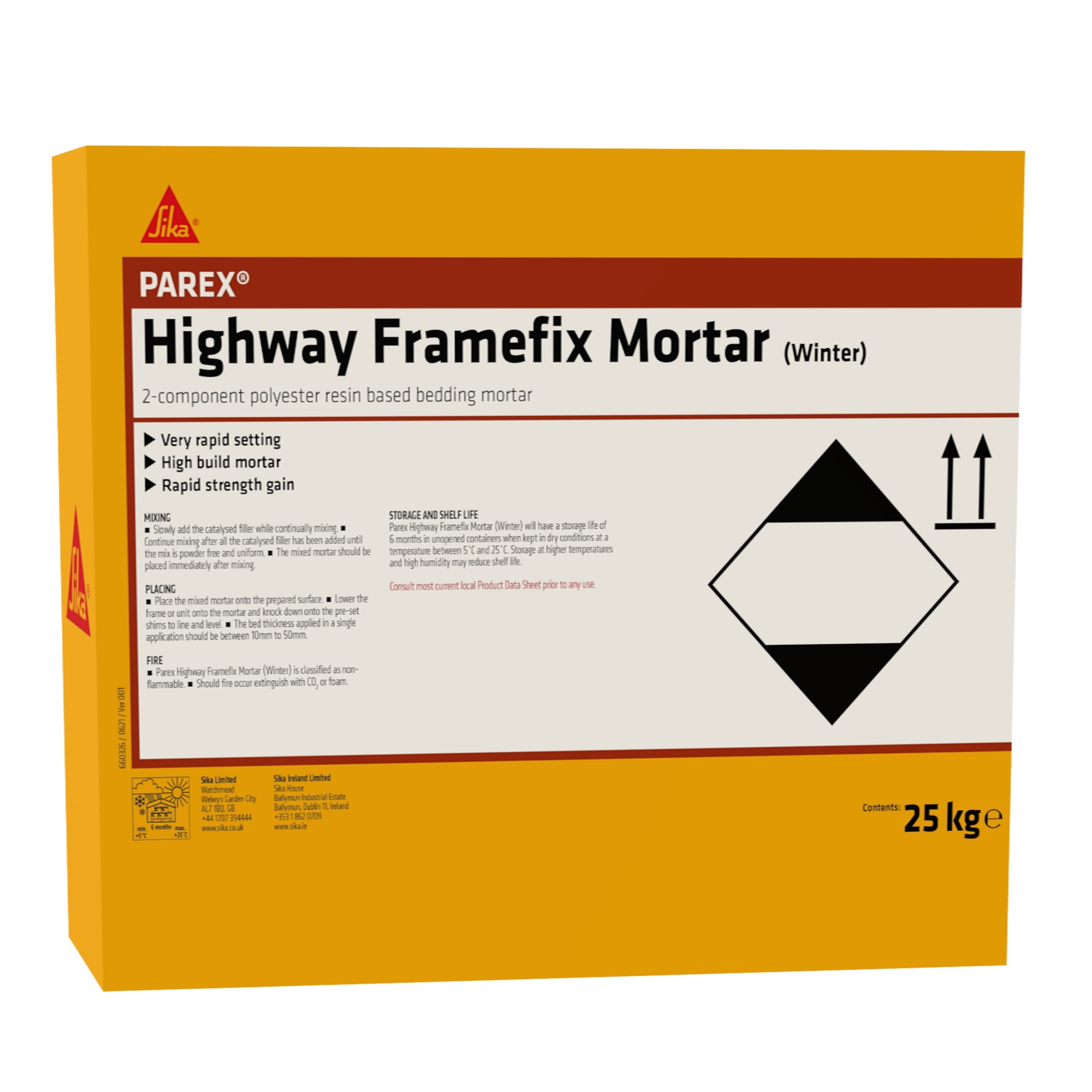

Parex Highway Framefix Mortar Winter

Parex Highway Framefix Mortar Winter is polyester resin based material used for the bedding and leveling of all types of frames in vehicular road surfaces in the most demanding situations. The product is supplied as a two pack system ready for onsite mixing consisting of two tins of base resin and two bags of catalysed filler.

The mixed mortar will harden to give rapid strength gain reaching 50N/mm2 in 1 hour allowing road opening to vehicular traffic within 3/4 to 1 hour. The placed frames will resist compressive and high impact loads The chemical mechanism will continue at temperatures down to 0°C with only a small increase in hardening time.

The hardened mortar is resistant to chemical attack from petroleum products and road salt. Two grades, Summer and Winter, are available.

Parex Highway Framefix Mortar complies with Highways Agency Advice Note 104/09 Design Manual for Roads and Bridges – Chamber Tops and Gully Tops for Road Drainage and Services: Installation and Maintenance.

Uses include:

- Re-bedding of raised manholes.

- Support of road furniture.

- Bedding of frames in new roads. Typical Mortar Properties @ 20°CWorking Time @ 12°

Framefix Mortar Winter Grade: 8-12 minutes (above 20°C setting will be rapid)

Specification Outline

Bedding of frames shall be carried out using Parex Highway Framefix Mortar as manufactured by Parex Ltd. The product must be stored, handled and placed strictly in accordance with the manufacturer’s instructions.

Quality Assurance

Parex Limited has an integrated business management system. This is externally accredited by UK CARES to BS EN ISO 9001:2015, BS EN ISO 14001:2015, BS ISO 45001:2018 and BES 6001.

Standards

Parex Highway Framefix Mortar has been tested in accordance with the relevant parts of BS 6319, HA104/09.

Instructions For Use

Preparation

Laitance and all loose material including dust, oil and grease should be removed in order to produce a sound substrate. Any loose brickwork should be re-bedded using a slightly resin rich mortar mix.

Mixing

Mixing must be carried out in the plastic package pail or a similar suitable mixing vessel. Suitable mixers include a slow speed high torque drill and Mortar Stirrer. For full pack mixing of Frame Fix Mortar pour all of the resin contained in the two tins within the pack into the mixing pail. Slowly add the catalysed filler while continually mixing.

Continue mixing after all the catalysed filler has been added until the mix is powder free and uniform. The chemical reaction of setting is rapid. The mixed mortar should be placed immediately after mixing. The working time may be extended in cold ambient conditions and may be shortened in hot ambient conditions.

Placing

Set suitable leveling shims onto the working surface ready to receive the frame or unit. Place the unit dry than check for level. Adjust if necessary. Place the mixed mortar onto the prepared surface and lower the frame or unit onto the mortar and knock down onto the pre-set shims to line and level.

The bed thickness applied in a single application should be between 10mm to 50mm. Thicker support beds can be achieved by applying further material as soon as the lower bed has hardened sufficiently not to distort under the additional work. The placed mortar will have hardened sufficiently to carry out further work, such as haunching, within 20 to 30 minutes depending on the surrounding ambient conditions and product grade.

Clean tools with Solvent before mortar has started to harden.

Limitations – Product not suitable as a wearing course. Do not place material if obvious setting is taking place.

Curing

No special curing is required at temperatures between 5°C and 35°C. For placing temperatures outside this range, refer to Framefix Grout data sheet or contact the Technical Service Department.

For more information on Parex Highway Framefix Mortar Summer click here

To view our extensive range of Parex products click here